Injection Mold Design Services

A Proper 3D Model is the Critical Link in Proper Injection Mold Design

Injection mold design is a complex process. Try to work with a mold specialist or your mold vendor as early in the design process as possible. Each vendor may have specific methods and material requirements, and often will only be able to work with certain file types and CAD platforms. Working with their engineers early in the process can streamline a design, and get you a better part at a lower cost.

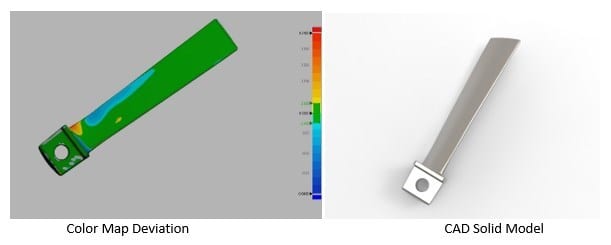

Complex geometry of molds is rarely dimensioned or created from drawings. Drawings serve as a rough visual representation of what the part needs to look like, and generally has only a few basic dimensions, what material the molded part is made of, and a volume or weight for general reference. The 3D model of the injection mold is the critical link to successful injection molding projects.

The design/mold engineers make final decisions on material, method of injection, cooling, parting lines, custom extraction requirements, shrinkage, and numerous other processing requirements. Any additional machining will be taken into account as well.

Based on the above factors, the mold engineer will decide if the part will be machined (CNC) to create the mold, printed (3D printer) to create the mold, or utilize a hybrid/specialized method based on part complexity. All of these processes will require alterations to a CAD model, with each process needing specific adjustments.

The 3D model we deliver is the “reference” part that they use to extract measurements and geometry, and use for the basis of any alterations that are required to make the mold. It serves as a digital prototype—and represents what the part should look like as the final product. The mold engineer applies many steps to get from the model to a finished product. As a general rule, all the modifications are made “in-house” by the molding firm for maximum efficiency and quality control of the final product, as they best understand the specific limitations of their equipment, materials utilized, and any post-molding finish requirements.

One half of a simple mold concept.

Contact Us to get the critical 3D model you need as the basis of your injection molding process.

Visit Our Portfolio Section to See Examples of Our Work

Explore the possibilities